| Feature | Benefit |

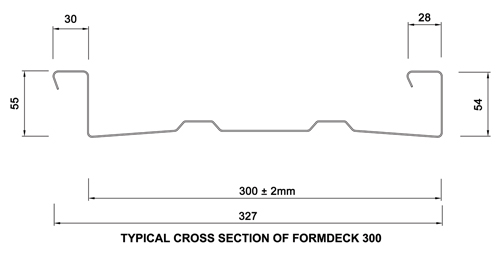

| 300mm Cover | - easy to walk on - easy to cut and trim |

| Hinge Side Laps | - no fasteners required |

| Quick Installation | - economical |

| Flat Soffit (no gaps) | - clean aesthetically pleasing with streamline finish - easy to finish paint or spray - no filler strips required - minimal seepage |

| Permanent Formwork | - becomes part of slab - reduces propping, formwork stripping and bottom reinforcement |

| Fire Rating Benefits | - FD300 unique closed rib profile reduces FER(fire emergency reinforcement) when encased in concrete |

| High Tensile Steel | - light weight with high strength - reduces propping - simple to install |

| Locally Made | - quick turnaround - design assistance and conversion - measure and scheduling service available |

![]()

FD300 is a cold rolled formed section manufactured from high-tensile (G550) steel. It is available in 0.75, 0.90 or 1.00 mm Base Metal Thickness (BMT). The galvanized coating thickness is a Z350 (350g/m²) in full conformance with AS1397. In special circumstances FD300 may be obtained in:

|

||||||||||||||||||||||||||||||

![]()

It has been tested and shown that the inter-locking ribs of the Formdeck300 when fully embedded in a concrete slab, will retain a majority of its strength through its ribs in exposed fire conditions for up to two hours. Further to this the rib strength can be used to reduce the quantity of bottom (FER) Fire Emergency Reinforcement mesh in slabs.

|

||||||||||||||||||||||||||||||

![]()

The anti-glare coating is applied to the pans only of the FD300, this ensures that the chemical bond between the deck and the concrete is fully effective, and hence does not compromise the composite slab performance. The non reflective coating reduces light reflection by more than 80% improving safety and on site working conditions. |

Formdeck300 comes available with a grey anti-glare coating. This coating is a water-based material that is applied on line during the production stage and dries within minutes.

Formdeck300 comes available with a grey anti-glare coating. This coating is a water-based material that is applied on line during the production stage and dries within minutes.